By Adeline Lopez

An innovative technology, developed with funding from the NIEHS Superfund Research Program (SRP), can deliver amendments that immobilize and degrade polychlorinated biphenyls (PCBs) in aquatic environments. The technology has proven effective in the field and resulted in millions of dollars in estimated cost savings at cleanup sites.

The Problem:

PCBs are a large and complex group of chemicals that were used in insulation, coolants, and electrical equipment. Although commercial production of PCBs was banned in the United States in 1979, they persist in the environment because of their stable chemical structure. PCBs can also accumulate in the aquatic food web, where they can pose a threat to human health.

SRP Solutions:

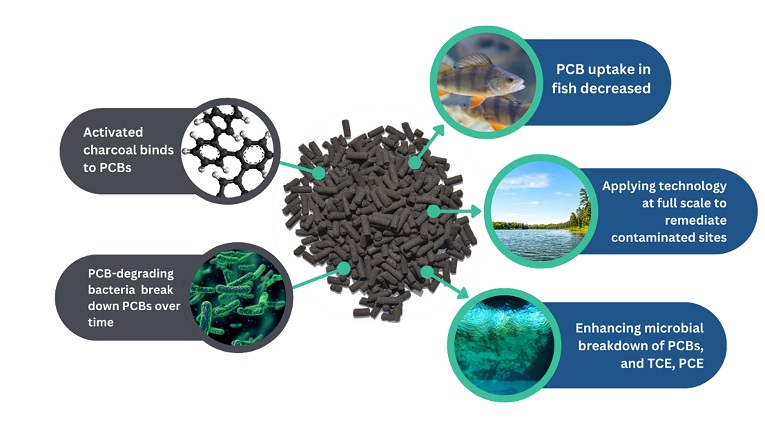

SediMite, developed by Upal Ghosh, Ph.D., of the University of Maryland, Baltimore County, and collaborators, uses activated carbon in the form of specialized pellets to bind to PCBs and reduce their bioavailability, or uptake by fish and other aquatic organisms. The technology can also be combined with microbes that break down PCBs, reducing their toxicity.

Ghosh, right, and colleagues collect sediment samples to measure PCBs. (Image from the DNREC YouTube video highlighting the work at the Christina River)

Documenting Effectiveness in the Field

- The approach reduces PCBs in sediment porewater and surface water in the field

- The technology lowers PCB levels measured in lake fish

Ghosh and his team collaborated with the Delaware Department of Natural Resources and Environmental Control (DNREC) to use the technology at Mirror Lake. They demonstrated that between 2013 and 2018, PCB concentrations in sediment porewater decreased by about 80% after applying SediMite. They also measured a 70% reduction in PCB levels in the lake’s fish.

Their success has important implications for human health because PCB contamination is the primary reason that fish consumption advisories are issued by DNREC and the Delaware Division of Public Health.

Building on this achievement, DNREC used an enhanced version of the SediMite technology in a new project to reduce PBCs in the Christina River. Ghosh and colleague Kevin Sowers, Ph.D., combined the activated carbon with microorganisms that can break down PCBs to both immobilize PCBs in the sediment and degrade them over time. After five months, SediMite enhanced with PCB-degrading microbes reduced the amount of PCBs in the sediment by approximately 25%. PCB concentrations decreased by around 35% in the surface water and 64% in sediment porewater.

Videos developed by DNREC depict the successes at Mirror Lake and the Christina River projects.

Building the Foundation

- Activated carbon reduces PCB bioavailability in the lab

- The technology offers significant cost savings compared to other clean-up methods

The technology builds on years of research by Ghosh and colleagues. SediMite was initially developed in part with SRP funding in an early project focused on optimizing the delivery method to apply activated carbon pellets to contaminated sites.

Ghosh had previously collaborated with Richard Luthy, Ph.D., an SRP grant recipient at Stanford University, to develop the novel concept of amending sediments with sorbents to reduce pollutant bioavailability. Their initial studies resulted in a method, patented in 2006, to stabilize persistent organic contaminants using carbon as sorbents and laid much of the groundwork for identifying potential barriers and future research needs to make the technology a viable reality, including the need for efficient methods to deliver the sorbents to sediment.

Ghosh then collaborated with Charlie Menzie, Ph.D., to develop SediMite to efficiently deliver amendments to sediments through a U.S. EPA Small Business Innovation Research program grant. Initial tests demonstrated that it was a feasible technology for use in the field. With SRP funding, the researchers scaled up their method to deliver activated carbon pellets from the lab to the field and patented SediMite in 2010.

SRP trainees in Ghosh's lab measure PCB levels in water and fish during early lab experiments with activated carbon.

(Photo courtesy of Upal Ghosh)

Ghosh continued his research in a second SRP-funded project aimed at evaluating whether fish uptake less PCBs after remediation with activated carbon. The team used lab studies and modeling approaches to demonstrate that fish can reduced their PCB uptake by as much as 87% after 90 days of treatment with activated carbon.

They also showed that SediMite decreased the assimilation efficiency of PCBs by up to 93%. Assimilation efficiency measures the amount of the contaminant that remains in the body compared to the amount that is excreted. This early work by the scientists included scaling up their remediation work to the field study at Mirror Lake.

The technology was implemented in full-scale to remediate a five-acre lake in Dover, Delaware in 2013. It was also selected as a component of the cleanup strategy for a contaminated sediment site in Middle River, Maryland, where the approach was estimated to cost approximately $22 million less than traditional methods, such as dredging and hauling.

Optimizing for Use at Scale

- Scaling up bacteria growth, dispersal, and deployment.

- Demonstrating effectiveness in the field.

- Collaborating in full-scale remediation projects.

The activated carbon pellets can easily deliver microorganisms across large areas of contaminated sediment to both sequester and degrade PCBs. (Photos courtesy of RemBac)

While developing and patenting SediMite, the researchers identified some limitations to large-scale application of the technology. To address these limitations, Ghosh and Sowers, in collaboration with environmental scientist Bennett Amos, founded RemBac Environmental to enhance the SediMite carbon pellets with PCB-degrading microorganisms. Rembac was funded in 2020 through an SRP small business grant.

In the first phase of their project, they tested methods to optimize growing and storing large volumes of PCB-degrading organisms over time. They also developed and tested methods to apply the microbes more uniformly and cost-effectively to high volumes of activated carbon pellets, enabling them to scale up their technology to broader commercial use.

In the second phase of their project, the team plans to field test the effectiveness and utility of their technology at the New Bedford Harbor Superfund site. They hope their findings will inform regulators and other stakeholders as different PCB clean-up strategies are considered.

In 2022, the Elizabeth River Project started using SediMite to remediate Paradise Creek, a 14-acre tributary to the Elizabeth River in Virginia that is contaminated with PCBs. Another full-scale project, led by EPA, is using SediMite to remove dioxin from sediments in the Scanlon Reservoir in Minnesota.

New Directions

In 2021, Ghosh and team were awarded a four-year SRP grant to develop carbon-based sorbent materials to enhance the ability of bacteria to break down PCBs in sediments and mixtures of tetrachloroethylene (PCE) and trichloroethylene (TCE) in groundwater. PCE and TCE are chemicals often used in manufacturing and are the most frequently detected volatile organic chemicals in groundwater.

By understanding the interaction between surface chemistry and microbial degradation, the team expects to develop new technologies to remediate PCBs, PCE, TCE, and other chlorinated contaminants often found in the environment.